The global fire safety equipment market reached USD 60.48 billion in 2025. Experts project it to hit USD 64.38 billion in 2026. This market shows significant growth, with forecasts reaching USD 96.82 billion by 2033. This represents a 6.0% Compound Annual Growth Rate. The market will expand at an 8.5% CAGR from 2025 to 2035. Brands must meet the demand for high-quality fire fighting equipment. Partnering with Chinese OEM/ODM fire fighting equipment suppliers offers strategic advantages. These partnerships unlock global market potential through expert manufacturing. A fire fighting equipment distributor can benefit greatly. ZheJiang World Fire fighting equipment, for instance, provides products like Fire Hydrants. This highlights Why Source Fire Fighting Equipment from China in 2026?

Key Takeaways

- Partnering with Chinese OEM/ODM suppliers offers cost savings and advanced manufacturing for fire fighting equipment.

- Chinese suppliers provide large production capacity and access to new fire fighting technology.

- Brands must check quality control, ensure clear communication, and protect their designs with legal agreements.

- It is important to choose suppliers with proper certifications and good after-sales support.

- Brands should research suppliers well and monitor production closely for successful partnerships.

Why Partner with Chinese OEM/ODM Suppliers for Fire Fighting Equipment?

Cost-Effectiveness in Fire Fighting Equipment Production

Partnering with Chinese OEM/ODM suppliers offers significant cost advantages. These manufacturers benefit from lower labor costs and efficient supply chains. This allows them to produce high-quality components and finished products at competitive prices. Brands can achieve higher profit margins or offer more attractive pricing to their customers. This cost-effectiveness does not compromise product quality. Instead, it provides a strategic financial edge in the global market.

Advanced Manufacturing Capabilities for Fire Fighting Equipment

Chinese OEM/ODM suppliers possess advanced manufacturing capabilities. They utilize modern technologies and sophisticated equipment. For example, injection molding produces fire helmet shells. This process melts high-performance thermoplastics or composite materials. It then injects them into precision molds. This method ensures helmets are lightweight, strong, and provide necessary protection against impact and penetration. Many suppliers, like Yinglong Fire Technology Co., Ltd., use sophisticated processing equipment and advanced testing and inspection equipment for their fire protection products. They follow a precise, quality-controlled process from raw materials to final packaging. This approach ensures durability, reliability, and compliance with international safety standards.

- Sophisticated Processing Equipment and Advanced Testing and Inspection Equipment: Manufacturers use these for fire protection products.

- Precise, Quality-Controlled Process: This approach ensures durability, reliability, and compliance with international safety standards.

- Button Processing: Specialized machines shape and refine control buttons for accuracy.

- Valve Cover Processing: The valve cover is precisely molded and finished for strong protection.

- Components Assembly: All critical components are assembled under strict supervision.

- Water Pressure Testing: Each unit undergoes rigorous testing to simulate emergency conditions.

- Spray Paint Coating: Products receive anti-corrosion, heat-resistant spray paint for durability.

Scalability and Production Capacity for Fire Fighting Equipment

Chinese OEM/ODM suppliers offer impressive scalability and production capacity. They can handle large orders and meet fluctuating market demands. This flexibility is crucial for brands experiencing rapid growth or seasonal spikes in demand. Their extensive manufacturing infrastructure allows for quick adjustments to production volumes. This ensures a consistent supply of fire fighting equipment.

| Order Type | Typical Lead Time (Days) |

|---|---|

| Standard Orders | 20-40 |

| Custom Orders | 35-50 |

| SCBA/Turnout Gear | Longer setup |

These lead times demonstrate their ability to manage diverse production requirements efficiently. This capacity allows brands to scale their operations without significant capital investment in manufacturing facilities.

Access to Innovation in Fire Fighting Equipment Technology

Chinese OEM/ODM suppliers provide brands with direct access to the latest innovations in fire fighting equipment technology. These manufacturers invest heavily in research and development. They continuously introduce advanced solutions to the market. For example, Fujian Longxiang Fire-fighting Equipment Co., Ltd. develops fire monitors with intelligent control systems. These systems automatically adjust water flow and direction based on fire conditions. This enhances operational efficiency.

Many Chinese companies focus on smart fire protection. Zhongxiaoyun Technology Co., Ltd. integrates IoT, big data, and cloud computing. They offer intelligent fire alarm, monitoring, and emergency management systems. This includes smart alarms with advanced sensors and smart fire suppression systems utilizing IoT technology. Furthermore, manufacturers like Sichuan Chuanxiao Fire Vehicle Manufacturing Co., Ltd. produce various advanced firefighting vehicles. These include water tank, foam, and special rescue vehicles. Jiangsu Suolong Fire Technology Co., Ltd. specializes in environmentally friendly fire extinguishing agents and systems. These include dry powder, foam, and gas extinguishing agents. Other innovations include firefighting drones and robotic firefighting vehicles. These advancements ensure brands can offer cutting-edge products to their customers.

Streamlined Supply Chains for Fire Fighting Equipment

Chinese OEM/ODM suppliers benefit from highly streamlined supply chains. This efficiency reduces lead times and logistics costs. China’s robust manufacturing ecosystem provides easy access to raw materials and components. This ensures a consistent and reliable production flow. Suppliers can quickly source parts and assemble products. This allows for faster delivery of finished fire fighting equipment to global markets. Brands can therefore respond quickly to market demands. They can also maintain optimal inventory levels. This streamlined process minimizes delays and improves overall operational efficiency for partner brands.

Leading Chinese OEM/ODM Fire Fighting Equipment Suppliers

ZheJiang World Fire Fighting Equipment Co., Ltd.

ZheJiang World Fire Fighting Equipment Co., Ltd. stands as a professional entity. It integrates design, research and development, production, manufacturing, and sales. The company commits to supplying high-quality fire fighting equipment to global customers. Its product range includes fire hydrants, fire hose nozzles, connectors, gate valves, check valves, ball valves, and flanges. They also produce fire pipeline connectors, fire hose reels, fire cabinets, fire extinguisher valves, dry chemical powder fire extinguishers, foam and water fire extinguishers, CO2 fire extinguishers, plastic parts, and metal parts.

The company operates from Yuyao City, Zhejiang Province. This location offers a beautiful environment and convenient transportation. The facility spans 30,000 square meters. It employs over 150 workers and professional technicians. ZheJiang World Fire Fighting Equipment Co., Ltd. uses advanced equipment and maintains strict quality control throughout production. All products comply with international standards. Customers globally accept these products. The company sells its products to countries and regions including America, Europe, Southeast Asia, the Middle East, and Africa.

To meet diverse customer requirements, the facility holds certification to ISO 9001:2015 Quality Management System. Furthermore, its products carry certifications such as:

- MED

- LPCB

- BSI

- TUV

- UL/FM

These certifications underscore the company’s dedication to quality and safety.

Xinhao Fire Protection Equipment Co., Ltd.

Xinhao Fire Protection Equipment Co., Ltd. offers an extensive array of fire safety products. Their primary product lines include various fire extinguishers such as DCP, CO2, automatic, portable, and foam water types. They also manufacture fire hoses, fire alarm systems, ship life-saving equipment, fire boxes, fire extinguisher series, fire hydrants, fire ladders, and other fire equipment series.

The company operates a modern production base. This base features advanced machinery. It includes 8 deep drawing machines, 1 automatic deep drawing machine, and 6 welding machines. Xinhao also utilizes 1 coating production line, 1 filling production line, and surface treatment machines. They employ 3 water pressure and air pressure testing machines, polishing machines, and forging presses. These facilities ensure efficient and precise manufacturing processes.

Xinhao Fire Protection’s comprehensive product offerings extend to:

- Fire Hose Boxes

- Fire extinguishers

- Fire extinguishers accessories

- Fire fighting equipment

- Fire hose reels

- Fire hose cabinets

- Fire monitors

- Extinguisher suppression systems

Their robust manufacturing capabilities, including 8 deep drawing equipment and 6 welding equipment, support high-volume production and consistent quality.

Zhejiang Feilong Fire Fighting Equipment Co., Ltd.

Zhejiang Feilong Fire Fighting Equipment Co., Ltd. specializes in essential fire safety components. The company focuses on manufacturing high-quality:

- Fire hose reels

- Hydrants

- Nozzles

They provide reliable solutions for various fire protection needs.

Shanghai Jindun Fire Equipment Co., Ltd.

Shanghai Jindun Fire Equipment Co., Ltd. is a prominent manufacturer in the fire safety industry. The company specializes in producing a wide array of fire protection products. They focus on delivering reliable and high-performance solutions for various applications. Shanghai Jindun serves both domestic and international markets. Their commitment to quality and innovation makes them a valuable partner for brands seeking OEM/ODM services. The company maintains strict quality control measures throughout its manufacturing processes. This ensures all products meet relevant safety standards and customer expectations.

FENAN Fire Fighting Equipment Manufacturer

FENAN Fire Fighting Equipment Manufacturer is a leading provider of personal protective equipment for firefighters and industrial workers. The company offers a comprehensive range of safety solutions. FENAN provides firefighting breathing apparatus. This includes self-contained breathing apparatus (SCBA), emergency escape breathing devices (EEBD), and trolley breathing apparatus. They also offer fire-resistant clothing. Additionally, FENAN supplies air compressors for refilling breathing apparatus cylinders. They manufacture gas masks and gas mask canisters. These items protect against hazardous gases and chemicals.

FENAN’s product portfolio includes:

- Breathing Apparatus:

- Firefighting SCBA

- MED SCBA

- EEBD

- Oxygen Breathing Apparatus

- Powered Air Purifying Respirator

- Long-tube Air Breathing Apparatus

- Trolley Mounted Breathing Apparatus

- SCBA Spare Parts:

- SCBA Mask

- HUD (Head-Up Display)

- Pressure gauge

- Lung Demand Valve (LDV)

- Backplate

- Cylinder Valve

- Air Compressor

- Gas Masks

- Gas Mask Filter

- Fire Resistant Clothing

- Breathing Air Cylinder

Shaoxing Safety Plus Fire Fighting Equipment Manufacturing Co., Ltd.

Shaoxing Safety Plus Fire Fighting Equipment Manufacturing Co., Ltd. is a comprehensive manufacturer of fire safety products. The company offers a broad selection of items designed for various fire protection needs. They focus on producing high-quality and reliable solutions for global markets.

Shaoxing Safety Plus’s extensive product range includes:

- Fire Extinguishers:

- Portable

- ISO Dry Powder

- EN3 Dry Powder

- UL Dry Powder

- SABS Dry Powder

- Mexican Dry Powder

- Wet Chemical

- Stainless Steel

- Foam

- Water

- Fire Hose Reels:

- Manual Swing

- Automatic Swing

- Fixed

- Accessories

- Others

- Fire Hoses:

- PVC Lining

- Rubber Lining

- Durable

- Double Jacket

- Fire Blankets:

- TUV EN

- AS/NZS

- Welding

- Fire Hydrants:

- Indoor

- Outdoor

- Water Way Systems:

- Landing Valve

- Fire Fighting Nozzle

- Coupling

- Extinguisher Filling Machines:

- CO2

- Powder

- N2

- Seamless Gas Cylinders:

- N2O

- CO2

- Oxygen

- N2

- Others

- Other Products:

- Fire Alarm

Macro Custom Fire Fighting Equipment Solutions

Macro Custom Fire Fighting Equipment Solutions excels in providing tailored fire safety products. This company specializes in creating custom fire extinguishers and ABC dry chemical powder. They also manufacture dry powder and fire extinguishers under a client’s specific brand name. This allows brands to offer unique products that meet their exact market needs. Furthermore, Macro Custom offers extensive customization options. They adjust the size, shape, and materials of fire extinguishing products. This ensures each item perfectly aligns with client specifications and design requirements.

Macro Custom Fire Fighting Equipment Solutions also offers competitive prices for these customized products. They ensure confidentiality with OEM/ODM partners. The company signs confidentiality agreements to protect client rights. This commitment builds trust and secures intellectual property for collaborating brands.

Safety Plus Industrial Fire Fighting Equipment

Safety Plus Industrial Fire Fighting Equipment provides a comprehensive range of industrial fire safety solutions. They offer essential items for various commercial and industrial settings. Their product line includes:

- Fire Cabinet

- Fire Extinguisher Filling Machine

- Car Extinguisher

- Fire Hose Reel Cover

- Fire Extinguisher Cover

- Extinguisher Cabinet

Safety Plus also manufactures a broader selection of critical fire safety tools. These products ensure robust protection across different environments. Their offerings include:

- Fire Extinguisher (including CO2 fire extinguisher and trolley extinguisher)

- Fire Hose Reel

- Fire Cabinet

- Fire Hydrant

- Landing Valve

- Extinguisher Accessory

- Fire Hose

- Fire Blanket

- Fire Hose Fittings

This diverse inventory allows brands to source a wide array of high-quality industrial fire fighting equipment from a single, reliable supplier.

Orena Fire Alarm System Manufacturer

Orena Fire Alarm System Manufacturer develops advanced fire detection and alarm systems. They produce a variety of solutions for different safety needs. Their product categories include:

- Conventional Fire Alarm System

- Addressable Fire Alarm System

- Visual Fire Alarm System

- Explosion-proof Fire Alarm System

- Wireless Fire Alarm System

- Combustible Gas Alarm System

- Suppression & Extinguishing System

- Emergency Lighting Evacuation System

- Emergency Voice Evacuation System

- Emergency Intercom Telephone System

- Standalone Alarms

- Fire Power Supply Unit

Orena also manufactures the innovative SmartEye H5800 visual intelligent fire alarm system. This system integrates advanced visual technology for enhanced detection capabilities. It provides reliable and efficient fire safety monitoring for various applications.

HAIJING FM200 Fire Suppression Systems

HAIJING offers advanced FM200 fire suppression systems, providing critical protection for sensitive environments. These systems utilize Heptafluoropropane (HFC-227ea, FM 200) as the extinguishing agent. This agent is colorless, odorless, and non-conductive. It leaves no secondary pollution and exhibits low toxicity. The system boasts high fire-extinguishing efficiency and does not deplete the ozone layer. HAIJING designs these systems to comply with GA400-2002 and ISO standards.

HAIJING FM200 systems find application in various critical areas where water-based systems could damage sensitive equipment. These include:

- Data centers

- Electrical rooms

- Server rooms

- Other areas where water-based systems are not suitable

The systems come in various volumes, from 40L to 150L, with a gas filling pressure of 2.5MPa and a maximum pressure of 4.2MPa. The spray duration is a rapid 10 seconds, and the working temperature ranges from 0-50°C. An automatic start-up delay time can be set from 0 to 30 seconds.

| Specification | Detail |

|---|---|

| Model NO. | SJ-GQQ |

| Standard | GB16670-2006 |

| Spray Duration | 10s |

| Working Temperature | 0-50°C |

| Automatic Start-up Delay Time | 0~30s |

| Volume (L) | 40, 70, 90, 100, 120, 150L |

| Gas Filling Pressure | 2.5MPa |

| Max Pressure | 4.2MPa |

| Working Voltage & Current | DC24V, 1.3A |

| Trademark | SJ / OEM |

| Origin | Fujian, China |

| HS Code | 842410090 |

| Agent Type | Heptafluoropropane (HFC-227ea, FM 200) |

| Agent Characteristics | Colorless, odorless, non-conductive, no secondary pollution, low toxicity, high fire-extinguishing efficiency, non-ozone destructive |

| Compliance | GA400-2002 and ISO standards |

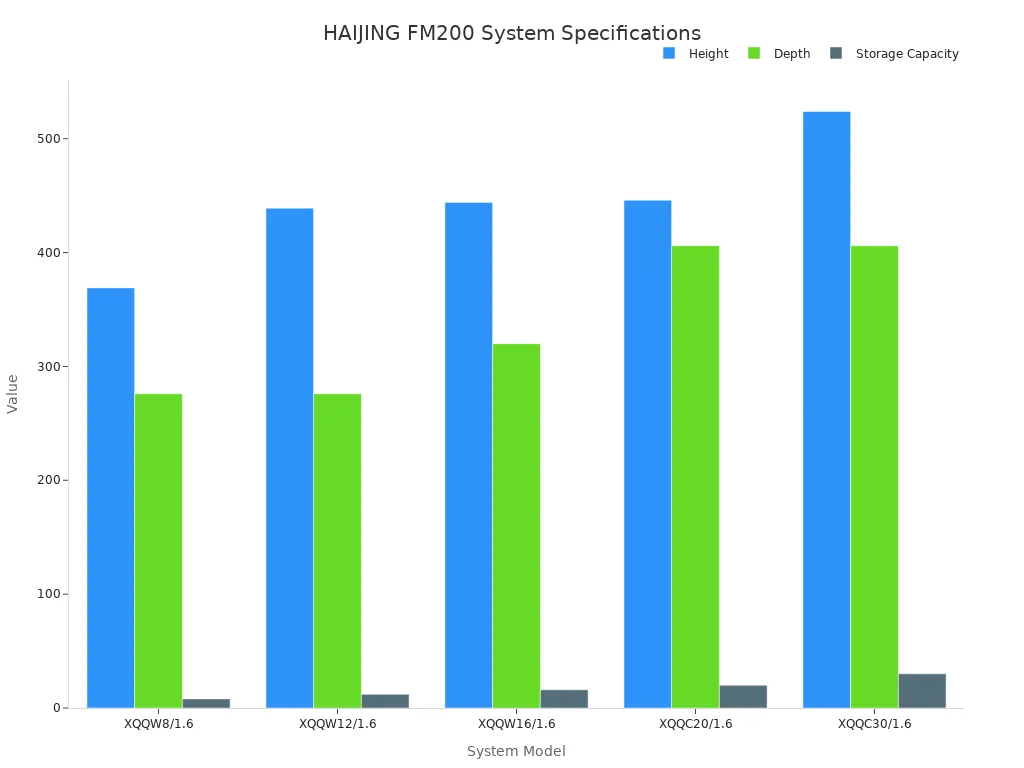

HAIJING offers different models, including XQQW (sprinkler heat responsive) and XQQC (electrical signal from smoke/heat sensor). These models vary in storage capacity, height, and depth.

Each system comprises several key components. For XQQW models, these include a fire sprinkler, pressure gauge, head valve, cylinder, and hanger. XQQC models feature a hanger, bolts and nuts, cylinder, name plate, head valve, pressure gauge, safety valve, nozzle, and solenoid driver. This comprehensive design ensures reliable and effective fire fighting equipment.

| Type | Component No. | Component Name |

|---|---|---|

| XQQW | 1 | Fire Sprinkler |

| XQQW | 2 | Pressure Gauge |

| XQQW | 3 | Head Valve |

| XQQW | 4 | Cylinder |

| XQQW | 5 | Hanger |

| XQQC | 1 | Hanger |

| XQQC | 2 | Bolts and Nuts |

| XQQC | 3 | Cylinder |

| XQQC | 4 | Name Plate |

| XQQC | 5 | Head Valve |

| XQQC | 6 | Pressure Gauge |

| XQQC | 7 | Safety Valve |

| XQQC | 8 | Nozzle |

| XQQC | 9 | Solenoid Driver |

CA-FIRE Valve Manufacturer

CA-FIRE Valve Manufacturer specializes in producing a wide range of valves essential for fire protection systems. They offer robust and reliable components crucial for effective fire suppression. Their product portfolio includes various types of valves designed to meet diverse system requirements.

CA-FIRE’s extensive valve offerings include:

- Fire Protection Foot Valve (Bottom Valve)

- Landing Valve Price Brass Material Landing Hydrant

- BS Type 65mm Copper Material 1.6MPa Fire Hydrant Oblique

- Gate Valve Monitoring Switch

- Full Bore Rubber Disc Check Valve With Ductile Iron Body

- Rubber Disc Check Valve – Fire Protection Anti-Backflow Valve

- OS&Y Gate Valve Supervisory Switch

- Fire System Water Flow Indicator – Durable Flow Monitor

- OS Y Flange Gate Valve

- Butterfly Valves

- Deluge Valves

- Alarm Valves

- Dry Pipe Valves

- Gate Valves

- Wet Alarm Valves

- Check Valves

- Pressure Reducing Valve

- Pressure Relief Valve

- Preaction Alarm Valve

- Other Valve

This comprehensive selection allows brands to source all necessary valve components from a single, trusted manufacturer. CA-FIRE ensures high-quality and compliant valves for various fire safety applications.

Key Considerations for Selecting an OEM/ODM Partner for Fire Fighting Equipment

Quality Control and Assurance for Fire Fighting Equipment

Selecting an OEM/ODM partner requires careful evaluation of their quality control processes. A reliable manufacturer implements strict quality assurance measures at every production stage. This includes raw material inspection, in-process checks, and final product testing. Brands must ensure the partner adheres to international standards and certifications. Consistent quality guarantees the safety and performance of the final fire fighting equipment. This commitment to quality protects the brand’s reputation and ensures customer satisfaction.

Effective Communication and Transparency

Effective communication forms the foundation of a successful OEM/ODM partnership. Brands must establish clear communication channels with their chosen supplier. Detailed contracts should define expectations regarding pricing, timelines, quality, and dispute resolution. Overcoming language differences often requires utilizing translation services. Scheduling regular video conferences helps mitigate time zone differences. Investing in cultural sensitivity training also improves understanding and interaction. This proactive approach fosters a transparent and productive working relationship.

Intellectual Property Protection for Fire Fighting Equipment Designs

Protecting intellectual property (IP) is paramount in OEM/ODM collaborations. NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreements are crucial legal frameworks. These agreements offer comprehensive protection beyond standard NDAs. The Non-Disclosure component ensures proprietary information, like trade secrets and product designs, remains confidential. The Non-Use clause prevents manufacturers from using shared IP for their own benefit or for other clients. The Non-Circumvention element prevents manufacturers from bypassing the business to deal directly with customers or suppliers. These agreements specify the legal jurisdiction and governing law, often advising the legal system of the manufacturer’s country for enforceability. They also outline penalties and remedies for breaches, deterring violations and securing the brand’s designs.

Certifications and Compliance Standards for Fire Fighting Equipment

Brands must prioritize certifications and compliance standards when selecting an OEM/ODM partner. These standards ensure product safety and market acceptance. For the European Union, CE Marking is mandatory for all imported products. Specific EN standards also apply, such as EN 2 for fire classification, EN 3 for portable fire extinguishers, and EN 54 for fire detection and alarm systems. Additionally, ATEX certification is legally required within the EU for equipment used in potentially explosive atmospheres. In the USA, standards primarily follow UL, CSA, and NEC guidelines. UL Certification is a key standard, and Amazon often requires specific UL certifications for products sold on its platform. Electrical equipment in hazardous locations in the United States needs approval from a Nationally Recognized Testing Laboratory (NRTL) and compliance with classifications like Division 1 and Division 2. These certifications confirm the quality and safety of the fire fighting equipment.

Scalability and Future Growth Potential

A strong OEM/ODM partner offers significant scalability and supports future growth. Brands need a manufacturer capable of adjusting production volumes quickly. This flexibility allows them to meet increasing market demand or seasonal fluctuations. A partner with robust infrastructure can handle larger orders as a brand expands its product lines or enters new markets. This capability minimizes the need for substantial capital investment in manufacturing facilities. It ensures a consistent supply of products, empowering brands to grow without operational bottlenecks. Evaluating a supplier’s long-term capacity and willingness to invest in new technologies is crucial for sustained success.

Logistics and Shipping Capabilities for Fire Fighting Equipment

Efficient logistics and shipping capabilities are vital for timely product delivery. Brands can choose various shipping methods from China. Sea freight is generally the most cost-effective for large shipments. Air freight offers faster delivery but comes with higher costs, suitable for valuable or time-sensitive goods. Incoterms define who pays for duties, taxes, and shipping risks. For example, DDP (Delivered Duty Paid) means the supplier handles all aspects, including customs and duties, delivering products directly to the buyer’s door. FOB (Free On Board) requires the buyer to take responsibility once goods leave China. A freight forwarder can arrange international shipping, customs clearance, and necessary paperwork. Third-party logistics providers (3PLs) offer additional services like warehousing and distribution. For sea shipping, brands consider full container load (FCL) or less than a full container load (LCL) based on cargo volume.

After-Sales Support and Warranty Policies

Evaluating a supplier’s after-sales support and warranty policies is crucial for long-term brand success. A robust support system ensures product reliability and customer satisfaction. Chinese OEM/ODM suppliers for fire fighting equipment commonly offer a 6-month warranty period for their products. This often comes with one-stop after-sales service to assist with any issues.

These suppliers provide various essential after-sales support services. These include:

- After-sales warranty

- Replacement policy

- Technical support, such as CAD and installation guidance

Many manufacturers offer a 12-month warranty from the date of delivery. This warranty typically covers defects in materials and workmanship under normal use. However, it usually excludes damage from misuse, accidents, unauthorized modifications, or natural disasters. Customers can return defective products for repair or replacement within the warranty period. This process is subject to inspection.

Beyond the warranty period, suppliers often provide lifetime maintenance services for their products. Customers are responsible for the cost of parts and labor for repairs outside the warranty. Technical support is readily available online, offering troubleshooting assistance. On-site support may be an option for complex issues, with customers covering travel and accommodation costs. Suppliers also ensure the availability of spare parts for a reasonable period after product discontinuation. They offer product operation and maintenance training for customers. Manufacturers aim to respond to service requests within 24 hours. Customers initiate the service process by contacting customer service with proof of purchase and a description of the issue. The supplier’s liability is limited to the repair or replacement of the defective product. Chinese law governs these services. Terms and conditions may be updated periodically.

Navigating the Collaboration Process for Fire Fighting Equipment

Initial Research and Due Diligence

Brands begin the collaboration process with thorough initial research and due diligence. This step ensures a reliable partnership. Companies must verify essential documents like business licenses, tax registration, and quality certifications, such as ISO 9001. They assess production capacity, technical expertise, and experience with similar projects. Requesting portfolios and contacting references provides valuable insights. Financial stability checks ensure the supplier’s long-term viability.

Conducting factory audits is crucial. These can be physical, on-site audits, often performed by a third party. They assess quality management systems, production line organization, equipment maintenance, and social compliance. Brands should request live video tours of the factory floor, storage areas, and QC labs. Reputable suppliers welcome such inspections. Verifying supplier credentials involves cross-checking certifications using official databases like UL or CE Notified Bodies. Companies also request copies of business licenses and validate export history through customs data tools.

| Metric | Benchmark | Why It Matters |

|---|---|---|

| On-Time Delivery Rate | ≥97% | Ensures supply chain reliability |

| Average Response Time | ≤2 hours | Indicates communication efficiency |

| Reorder Rate | <15% | Suggests high buyer satisfaction |

| Customer Review Score | ≥4.7/5.0 | Reflects consistent product and service quality |

Request for Quotation and Sample Evaluation

After initial due diligence, brands issue a Request for Quotation (RFQ). This document clearly defines product requirements. Key elements in an RFQ for fire fighting equipment include an introduction explaining the objective and equipment type. It details technical specifications such as chassis type, engine specifications, pump capacity, and tank size. Performance standards, desired acceleration times, and braking distances are also specified. The RFQ requires vendors to provide documentation and certificates for compliance with industry standards. It also outlines selection criteria, competitive pricing, and warranty provisions.

After receiving quotations, brands order and test samples. This step is vital for evaluating product quality. They assess stitching integrity, inner lining comfort, heat resistance through controlled flame tests, and waterproof layer effectiveness. Samples should come directly from the factory production line, not from an office. This ensures they represent actual manufacturing quality.

Contract Negotiation and Agreement

Successful collaboration culminates in contract negotiation and agreement. This phase establishes clear terms and conditions for the partnership. The contract defines expectations regarding pricing, production timelines, quality standards, and dispute resolution mechanisms. It also addresses intellectual property protection. Brands must ensure the agreement covers all aspects of the manufacturing process and product delivery.

Production Monitoring and Quality Checks

Brands must actively monitor production and conduct rigorous quality checks. This ensures the manufacturer adheres to agreed-upon standards. Regular factory visits or third-party inspections provide crucial oversight. These checks verify raw material quality and assess in-process manufacturing. They also confirm final product assembly. Manufacturers often implement a multi-stage quality control system. This includes initial sample approval, pre-production checks, and during-production inspections. A final inspection before shipment ensures compliance with all specifications.

Tip: Implement a clear inspection plan. This plan should detail checkpoints and quality criteria at each production stage.

For fire fighting equipment, critical checks include pressure testing for hoses and cylinders. They also involve functional tests for nozzles and valves. Electrical components in alarm systems undergo performance verification. Adherence to international safety standards, like UL or CE, is paramount. Brands should receive detailed quality control reports. These reports document inspection results and any corrective actions taken. This proactive approach minimizes defects and ensures product reliability.

Post-Production Support and Feedback

Effective post-production support and feedback mechanisms are vital for long-term partnerships. A reliable OEM/ODM partner offers comprehensive after-sales service. This includes technical assistance, spare parts availability, and warranty claims processing. Brands should understand the supplier’s warranty policies. They need to know the duration and coverage for defects.

Note: Most Chinese OEM/ODM suppliers offer a 6-12 month warranty on fire fighting equipment.

Establishing a feedback loop allows continuous improvement. Brands provide feedback on product performance and customer satisfaction. This information helps the manufacturer refine processes and product designs. It also addresses any recurring issues. Regular communication post-delivery strengthens the relationship. It ensures both parties work towards mutual success. This collaborative approach fosters trust and leads to better products in future collaborations.

Partnering with Chinese OEM/ODM suppliers offers significant strategic advantages for brands. These collaborations empower brands through expert manufacturing, providing cost-effective production and access to advanced technology. This approach ensures high-quality fire fighting equipment. Brands can future-proof their fire safety product lines, meeting evolving market demands and maintaining a competitive edge.

FAQ

What are the primary advantages of collaborating with Chinese OEM/ODM fire fighting equipment suppliers?

Brands gain significant cost-effectiveness and access advanced manufacturing capabilities. These partnerships offer scalability, innovative technology, and streamlined supply chains. This helps brands meet global market demands efficiently.

How can brands ensure quality control when partnering with Chinese manufacturers?

Brands should select partners with strict quality assurance processes. This includes raw material inspection, in-process checks, and final product testing. Verifying international certifications like ISO 9001, UL, or CE is also crucial.

What measures protect intellectual property (IP) when working with Chinese OEM/ODM suppliers?

Brands should use NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreements. These legal documents protect proprietary designs and trade secrets. They prevent suppliers from misusing or sharing confidential information.

What certifications are important for fire fighting equipment from Chinese suppliers?

Essential certifications include ISO 9001 for quality management. Product-specific certifications like UL, CE Marking, LPCB, BSI, and TUV ensure compliance with international safety standards. These validate product reliability.

How long does the typical collaboration process take with a Chinese OEM/ODM supplier?

The timeline varies based on product complexity and order size. Initial research and due diligence can take weeks. Production lead times for standard orders typically range from 20 to 40 days. Custom orders may require 35 to 50 days.